With the continuous expansion of the company’s business, our workforce is also growing, and a group of new employees joined Everich. In order to make new employees familiar with the business and production process more quickly, the personnel department organized a visit to our factory, namely Kingvac, which is a leading stainless steel water bottle factory in Quzhou China, and mainly manufacture insulated water bottles, tumblers, water jugs, BPA free water bottles, and other drinkware. Moreover, we will visit the following three sites: laboratory, sample room, and manufacturing workshop.

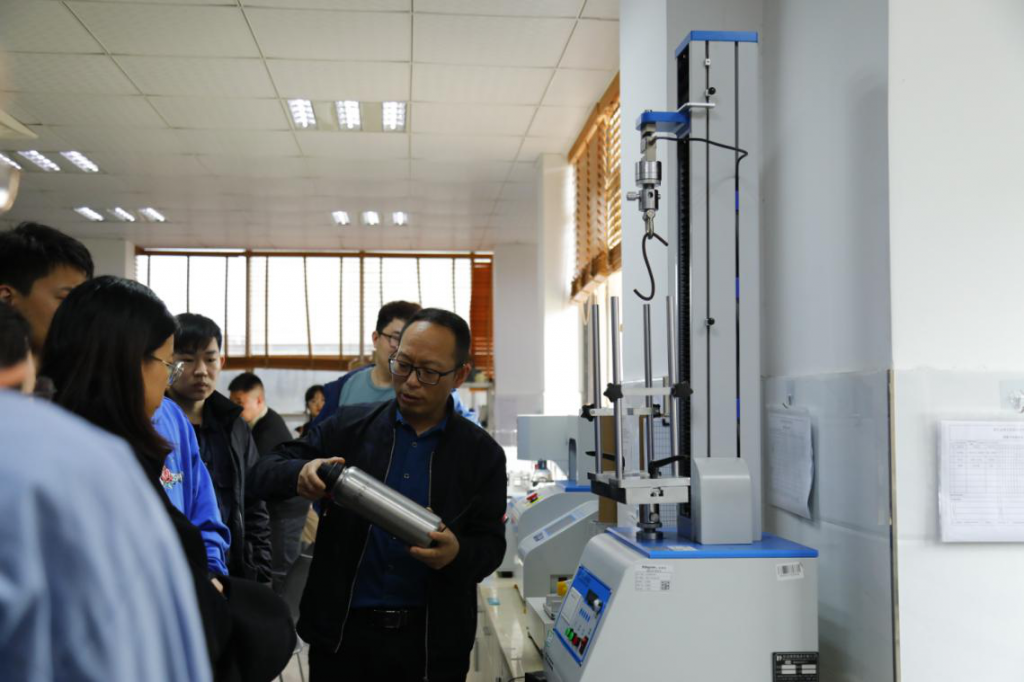

Site One: Kingvac Laboratory

There are fifteen precision instruments in the laboratory and every bottle produced by Kingvac needs to pass all the tests including Automatic Bursting Strength Test, Button Lid Life Test, Carton Drop Test, Color Assessment, Desktop Tensile Test, Dish Washer, Humid and Temp Programmable Test, Low-Temperature Test Multiplex Temperature Test and so on. Director Chen introduced the equipment in the laboratory, after listening to his explanation, everyone realized that ordinary bottles are not ordinary, still need to pass many tests to reach the hands of clients.

Site Two: Stainless Steel Water Bottle Factory’s Sample Room

Different styles of bottles were displayed in the largest sample room of Kingvac, which caused a lot of discussions among the new employees.

Site Three: Vacuum Insulated Bottle Manufacturing Workshop

Let’s follow Everich’s new recruits and learn the manufacturing process of vacuum insulated stainless steel water bottles in detail step by step.

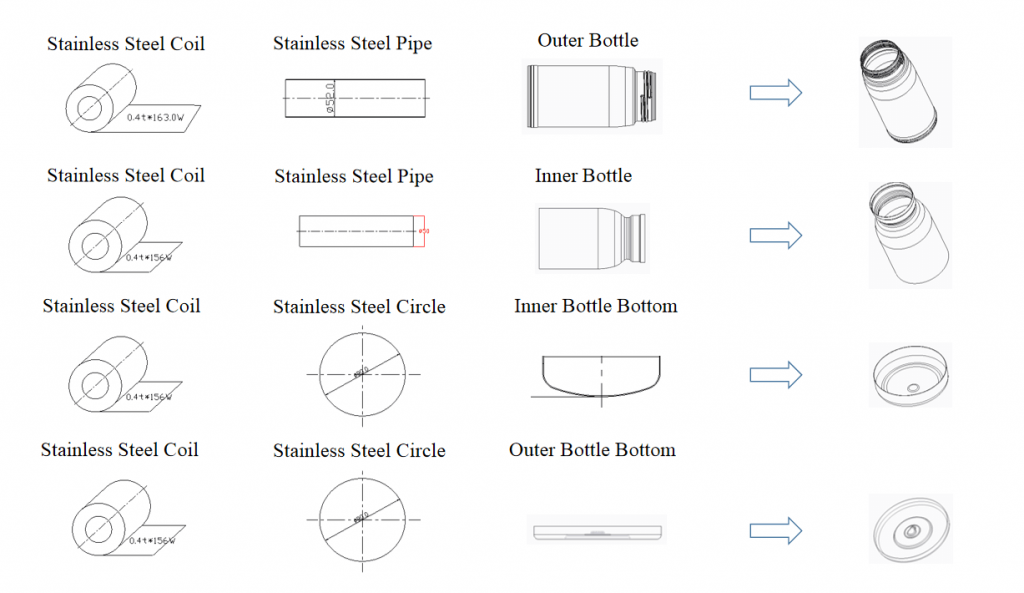

Brief Description:

Stainless Steel Pipe –> Produce outer bottle, inner bottle, outer bottle bottom, inner bottle bottom –> Assembly & Welding –> Vacuuming –> Decorating –> Testing –> Packing

Detailed Instruction:

1. Manufacture Outer Bottle & Inner Bottle

①Pipe Cutting: Cut raw material – stainless steel tube – to the appropriate length.

②Water Expansion: Stainless steel pipe is the raw material of this method. First, place the stainless steel tube on the water expander. The pipe expands into a bottle under enormous pressure. In this way, the resulting bottle has no bottom, so a round stainless steel plate is welded to it to form a complete bottle.

③Separating: Cuts off the two shells after water expansion with the instrument cart.

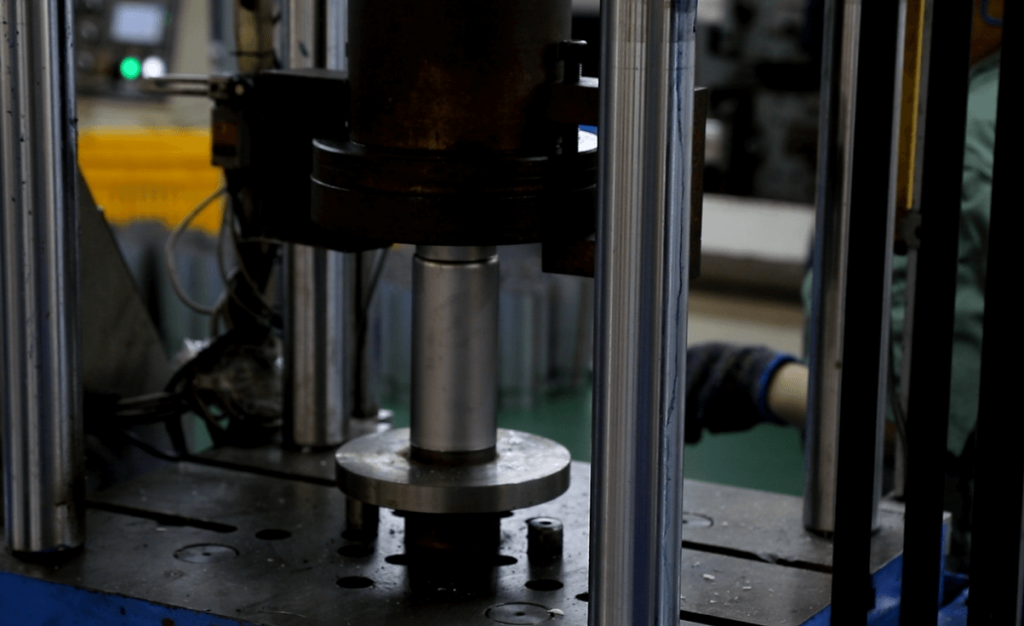

④Positioning & Shaping: Uses a large press, you can get the outer bottle you want, and ensure that the size of the product meets the requirements of the process drawings, and there should be no obvious defects such as wire drawing or cracking in the mouth.

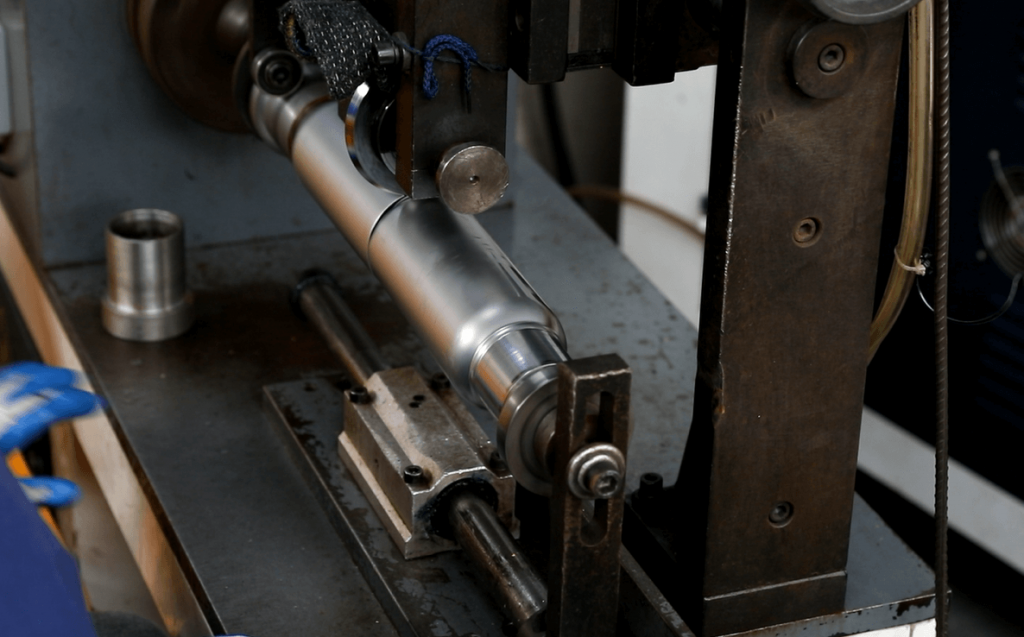

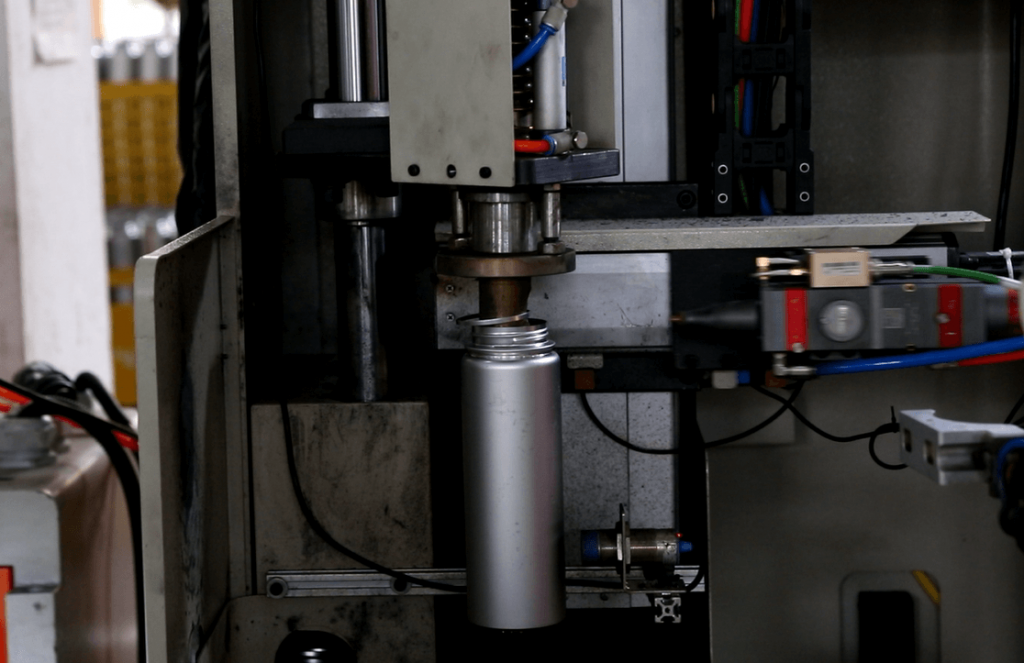

⑤Necking: Uses a machine to squeeze the upside of the bottle to be a bottleneck.

⑥Thread Rolling: Threads are made with a special threading machine. Adjust the thread depth to meet the size requirements.

⑦Flat Mouth & Bottom: Cuts the excess part of the mouth and bottom.

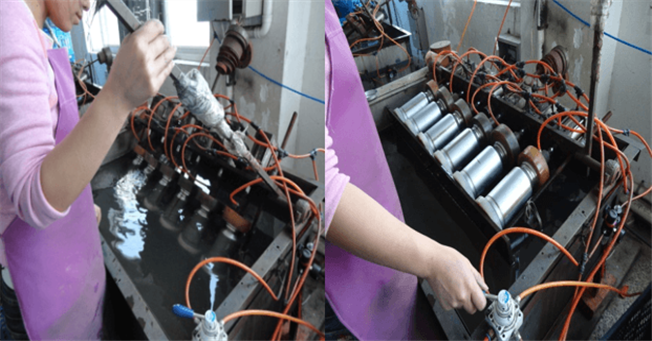

⑧Ultrasonic Cleaning: Removes lubricating oil and dust during molding.

2. Assembly (Bottle Mouth Matching)

①Assemble the inner bottle and the outer bottle together by pressing the machine.

②Assemble the round bottom to the bottle by pressing the machine.

③Weld the outer bottle and the bottle bottom to prepare for vacuum insulation.

3. Water Leakage Test

Check whether the welding of the inner and outer bottles is in good condition, and eliminate the unqualified products.

4. Vacuuming

Using the tailless vacuum technology of the machine, the vacuuming standard shall be strictly followed. A vacuum is formed between the inner tank and the outer bottle, thereby preventing heat transfer, providing insulation, and preventing hot hands.

5. Mechanical Polishing

Polish the surface of the outer bottle to ensure that the mouth of the bottle is smooth and shiny. There must be no obvious wire drawing, scratching, black wire, and pits.

6. Temperature Test / Insulation Test

Blow hot air into each bottle. If the outside of the bottle is kept cool, it means that the heat from the hot air will not be diverted and the bottle is vacuum insulated. On the contrary, if the bottle gets hot, there is a problem with vacuum insulation.

7. External Coating

The bottle is now ready for external coating – powder coating or spray painting. Kingvac is capable of doing both spray painting and powder coating processes.

8. Pattern and Logo Printing

Print the pattern design and logo on the bottle with various techniques – screen printing, thermal transfer printing, water transfer printing, laser etching, and so on.

9. Packing

After inspecting each bottle, including visual inspection and lid leak test, the bottle is placed in a separate bag for packaging.

Kingvac, the stainless steel water bottle factory covers an area of more than 7000m ², and the annual bottle production capacity is up to 20 million. As the leading stainless steel water bottle factory in China, Everich is worthy of your trust.