Plastic is a widely used material, but also professional materials. No matter industrial design or mechanical design, plastic products can be seen everywhere in our daily life. Next, I will introduce the common plastic material numbers and their characteristics for you.

In today’s highly informed age, most housewives are aware of the number 5 plastic used in microwave ovens, and many of them subconsciously pick out a triangle when they get a plastic container and carefully identify the number. But not many people really know these numbers, which raises a lot of questions. For example, is plastic number 5 the safest? So in order to make better use of plastic numbers to improve the quality of life, the first thing we should do is figuring out what the plastic numbers mean.

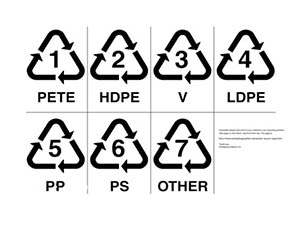

The triangle on the plastic container, is a sign of recycling actually. Numbers is the mark of the entry into the channels of different recycling. In other words, when recovery specialist saw the plastic bottles on the no. 1, knew that should be recycled by means of channel 1. What’s more, numerical magnitudes has nothing to do with the nature of the bottle itself

There are about 140 commercially available plastics, about 30 are used daily. But there are only seven types of plastic that are large enough to be recycled in the same direction, that’s why there are only seven numbers in the triangle: 1-7. Each number corresponds to a different plastic variety, it’s PETE, HDPE, PVC, LDPE, PP, PS, PC in turn. Each abbreviation has a “P” in it, which means “Poly-” in English.

Symbol 1: PET (polyethylene terephthalate)

Soft and transparent bottles or cans are almost made of PET, it’s beautiful and generous, with low price.

No. 1 plastic PET, the scientific name of polyethylene terephthalate, also referred to as polyester plastic. It’s common in life, the current beverage bottles and food oil bottles are almost all used this plastic. If the molecular weight of PET is large enough, it can be used in the fiber industry.

PET is characterized by high transparency, water resistance and oil resistance, but it is not very heat-resistant. Many people are aware of this phenomenon, that when you use a normal mineral water bottle to receive hot water from a water fountain, the bottle begins to be deformed, and the temperature is about 85 degrees.

Symbol 2: HDPE (high-density polyethylene)

Opaque and hard bottles or cans are made of HDPE, it has strong endurance and widely used in daily product container.

Plastic No. 2, HDPE, or high-density polyethylene, is the easiest to find in your bathroom as a chemical container, and is also used in many large beverage bottles.

Different from PET, HDPE is highly crystalline, so it appears opaque and harder, even a little brittle. Because of its high strength, fall resistant and impervious to light, daily products often use plastic No. 2.

Similar to PET, No. 2 plastic is not very heat-resistant, it’s a little bit stronger than PET, however, it deforms easily after 100 degrees Celsius.

Symbol 3: PVC (polyvinyl chloride)

Plastic No. 3, PVC, also known as polyvinyl chloride, is the only one of the seven plastics not recommended for contact with food because it contains chlorine. In fact, the chlorine in the material is not easily dissociated under normal conditions of use, although No. 3 plastic is rarely seen in food containers. PVC is also the only one of the seven plastics that must use plasticizer, which allows it to change its state from soft and elastic to hard and brittle.

Since PVC can present a soft and elastic side, it can simulate some USES of rubber or leather, such as artificial leather, which is widely used in the interior of Japanese cars, disposable inspection gloves, floors, tablecloths, plastic shoes. Besides PVC prices are much lower than natural rubber and polyurethane artificial leather.

Symbol 4: LDPE (low-density polyethylene)

LDPE is not good at keeping fresh, but it is still one of the most ideal materials for plastic wrap

Plastic No. 4 HDPE, and plastic No. 2 are brothers, technically called low density polyethylene.

But essentially 2 and 4 have different structures, except that the monomers are all ethylene.

HDPE’s transparency is relatively high, so we can mainly see it in plastic wrap, plastic bags and other aspects in our daily life.

Symbol 5: PP (polypropylene)

PP is a very pleasing plastic, the combination between PP and microwaves using noodles and sausages and solve the eating problem for long time not to go out people.

No. 5 plastic PP is our star plastic polypropylene, the most common than the button. At present, the vast majority of microwave oven special plastic containers on the market are PP plastic, because of its heat resistance and chemical stability is higher.

This kind of plastic are actually very close to No.2 plastic, crystallinity is lower than No.2 slightly, it’s translucent state commonly, the hardness with No.2 differ not too much.

More than any other plastic, No. 5 is used in food, not only in containers, but also in flexible packaging, and the BOPP film that forms the outermost layer of a cigarette case.

In addition, at present, the household water pipe commonly used in the new residential area is recommended or mandatory use PPR pipe, also is polypropylene material likewise, besides safety consideration, because it has the characteristic of hot melt, easy to process.

The polypropylene industry is also a standard to measure the level of a country’s industry.

Symbol 6: PS (polystyrene)

Do not think PS made lunch boxes are Low, at least they will keep some of the small restaurants alive.

PS 6, polystyrene, is a legendary plastic.

There was a time when plastic No. 6 was everywhere, especially on both sides of Chinese railways, but nearly 20 years later, many people have forgotten the “white pollution”.

Up to now, the important use of No.6 plastic is still foamed plastic, the polystyrene board in the home decoration refers to this kind of plastic, but in the food aspect the status is reduced a lot, generally in the instant noodles, the family bucket of these food packaging is still widely used, foam lunch box of course, but many people will refuse to use.

It should be noted that plastic No. 6 itself is transparent. If you are bored studying disposable drink cups on the plane, you will find that plastic No. 6 is mostly used. Of course, if you drink hot drinks like coffee or tea, you will only see paper cups or plastic No. 5.

Symbol 7: PC (polycarbonate)

The PC is a beautiful plastic, and it’s pretty strong, so we don’t have to worry about the cup breaking anymore

No. 7 plastic PC is not a PC, it’s polycarbonate, but it has to do with PCS, a lot of them are PC plastic.

Some places say that Number 7 stands for “other plastic,” which is true, but because of the widespread use of PCS, number 7 is now basically equivalent to polycarbonate plastic.

In the case of electrical appliances, PCS and another engineering plastic ABS dominate the market, while in the food industry, space cups, water dispenzer buckets and baby bottles are the most common.

Its outstanding feature is high strength, not easily broken, a bit better PC shell can not be broken, for example, the famous brand Nokia. The iPhone5C also made the plastic more widely known in the world.

Symbol 8: PMMA (polymethyl methacrylate,)

An additional plastic material that you hear a lot about.

Acrylic is an artist in plastic. PMMA, the scientific name for it is polymethyl methacrylate, and it has the resounding name of plexiglass. There is a large category of plastic called “acrylic,” and PMMA is the most representative material in acrylic resin.

PMMA material is one of the great revolution, because the refractive index of a glass is excellent and strength similar to the crystal, so after the birth of more than one thousand years, it makes no material issued a challenge to the glass. Only has the PMMA, and this kind of plastic, light weight, good strength, high refractive index, no sharp objects after crushing, hot cold resistance is good, in addition to the surface easily scratched, it can be described with perfect.

Accordingly, Acrylic replaced glass in industrial material respect not only those include a lot of use that food packaging includes, also have outstanding application in handicraft respect, the man-made gem with common on door shade and droplight, canvas “propylene” it is acrylic material.

In addition to the above, there are many plastics in daily use, and more importantly, PLA polylactic acid EVA ethylene-vinyl acetate copolymer POM, polyformaldehyde, PF phenolic resin, EP, epoxy resin (PF and P in EP are not Poly- abbreviation), MF, MF, etc.

EVERICH produces the wholesale tritan bottles, using a new copolyester, called: tritan copolyester. Different from producing BPA by PC hydrolysis, modern medicine believes that BPA will affect human health (including animals) exceeds the certain dose and tritan has been certified by the US Food and Drug Administration (FDA) and has designated the material for infant products in Europe and America.