A stainless steel bottle mold is a tool used to manufacture a range of bottle designs and sizes that can be used for personal or commercial use. Creating your own stainless steel water bottle mold provides the ability to customize bottle designs and control the quality and cost of the production process.

Preparing for the Mold-Making Process

Identifying the bottle design requirements involves understanding the desired shape, size, and capacity of the finished product. Conducting market research and analyzing trends helps to understand the demand for different bottle types and identify competitors’ products and prices.

Choosing Appropriate Processing Methods and Manufacturing Processes

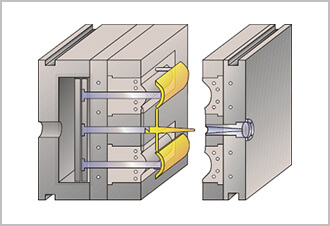

Different bottle designs and requirements call for specific processing and manufacturing processes, including CNC machining, hot stamping, injection molding, and others. Choosing the appropriate processes based on specific requirements ensures a high level of accuracy and quality during design and mold creation.

Designing the Stainless Steel Bottle Mold

1. Sketching and conceptualizing the bottle mold design using pen and paper can help to create an initial idea of the mold.

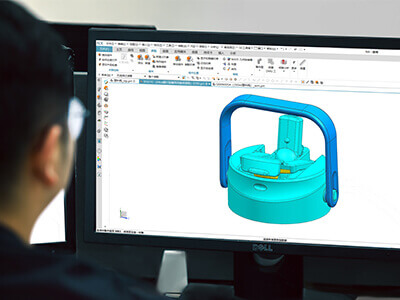

2. Leveraging 3D modeling software allows for precision and accuracy in designing the mold.

3. Factors to consider when designing the mold include the material of the mold, overall structure, shape, and size.

Fabricating the Stainless Steel Bottle Mold

Once the mold is designed, it can be manufactured using the selected fabrication process.

Testing and Adjusting the Stainless Steel Bottle Mold

1. Identifying potential issues and areas for improvement are important steps to ensure the quality of the molded products.

2. Adjusting the mold design and refining the production process helps to improve efficiency and quality while reducing production costs.

Mold Maintenance and Longevity

1. Proper cleaning and maintenance procedures for stainless steel molds are critical to maintaining their longevity.

2. Preventing corrosion and ensuring mold longevity involves conducting regular inspections and addressing any issues immediately.

3. Regular inspections and troubleshooting techniques can help identify common mold issues and the need for replacement equipment.

The Cost of Making a Mold

1. The cost of making a mold includes research and development, materials, and production costs.

2. Factors influencing pricing for stainless steel bottle molds include the complexity of the design and manufacturing process, materials used, the precision required, and others.

Frequently Asked Questions (FAQs)

Q: How long does it take to create a stainless steel bottle mold?

A: The time required to create a stainless steel bottle mold varies depending on the design, size, and complexity of the mold, typically taking several weeks to several months.

Q: What is the expected lifespan of a stainless steel bottle mold?

A: Stainless steel molds are durable and corrosion-resistant, and typically have a lifespan of thousands of uses.

Q: How to ensure the quality of the bottles produced using the mold?

A: The quality of the mold can impact the quality of the bottles produced, therefore careful testing of the mold and refining the production process can help ensure high-quality finished products.

Q: What is the cost range for creating a stainless steel bottle mold?

A: The cost of producing a stainless steel bottle mold can vary widely depending on a number of factors. Generally, molds can cost anywhere from a few thousand dollars to tens of thousands of dollars.

Q: Can stainless steel bottle molds be used for different bottle sizes?

A: Depending on the design of the mold, it is possible to use the same mold to produce bottles of different sizes. However, for optimal results, it is often best to use a mold designed specifically for each bottle size.

Conclusion

Everich is a company founded in 2000, dedicated to designing, manufacturing, and selling high-quality stainless steel water bottles, thermoses, and cutlery. Now also have cooler bags and home appliances. The company not only has a significant presence in the Chinese market but also has a diverse customer base worldwide.

Everich has advanced mold-making capabilities, based on years of production experience and professional technical expertise, and is committed to providing customers with high-quality and high-precision molds.

Firstly, Everich’s mold design team proficiently uses software such as CAD, CAE, and CAM for mold design and production. This design process ensures the accuracy, consistency, and repeatability of the molds.

Secondly, Everich uses high-performance tool steels and advanced heat-treating techniques to manufacture molds and adopts precision processing technology and simulation techniques in the perfect mold processing flow to control machining accuracy and reduce waste rates.

In addition, Everich regularly inspects and maintains production equipment to ensure that its equipment is always in optimal condition, thereby improving mold production efficiency and accuracy.

Finally, Everich also has a professional mold trial team that can customize mold production according to customer’s specific needs to meet their special requirements.

Therefore, Everich has comprehensive technology and production capabilities in the field of mold making, can provide customers with high-quality mold products, and customize molds that meet their specific requirements.

Everich welcomes customers with custom mold-making needs to send inquiries to us. We take pride in our advanced mold-making capabilities and our ability to meet our customers’ special requirements. Our professional and experienced team can provide customized mold-making services that are tailored to your needs. From design to manufacturing, we use the latest technology and quality materials to ensure that our customers receive high-quality and precision molds. Furthermore, we are committed to providing excellent customer service and strive to establish long-lasting relationships with our clients. So, if you are looking for a reliable partner for your custom mold-making needs, don’t hesitate to contact Everich today.